Dental Vacuum Plant

Dental vacuum plants are used in dental hospitals’ operation theatres, clinics and laboratories. They are used to remove air, blood, saliva, amalgam, detritus, tooth pieces, etc. with a high flowrate using a specially designed cannula that exist during treatments. These are removed at a speed of 15-20 m/s. The solid and liquid wastes collected into the disinfection vacuum tank are released to the drainage system after disinfection process.

Dental vacuum plants are designed and produced complying with Medical Devices Directive 93/42/EEC, HTM 2022 Dental Compressed Air and Vacuum Systems, ISO 1497, ISO 13485, EN 46001 standards.

Design and flow calculations of a dental vacuum plant are done according to HTM 2022:2003 Dental Compressed Air and Vacuum Systems standard and the capacity is specified.

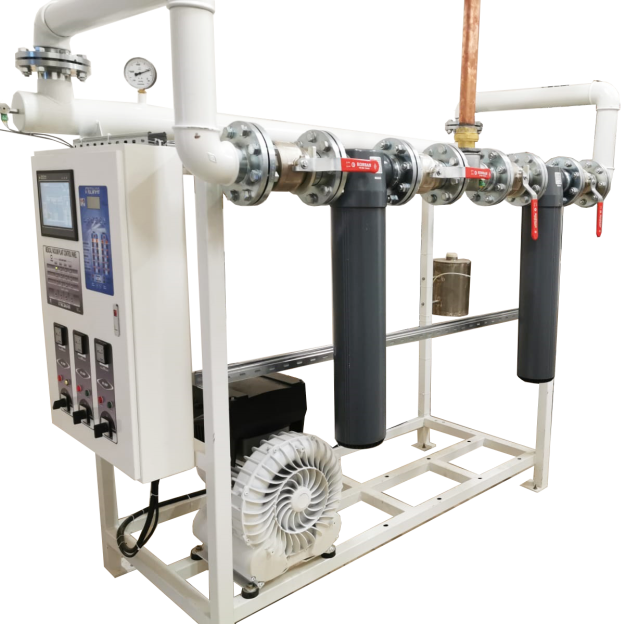

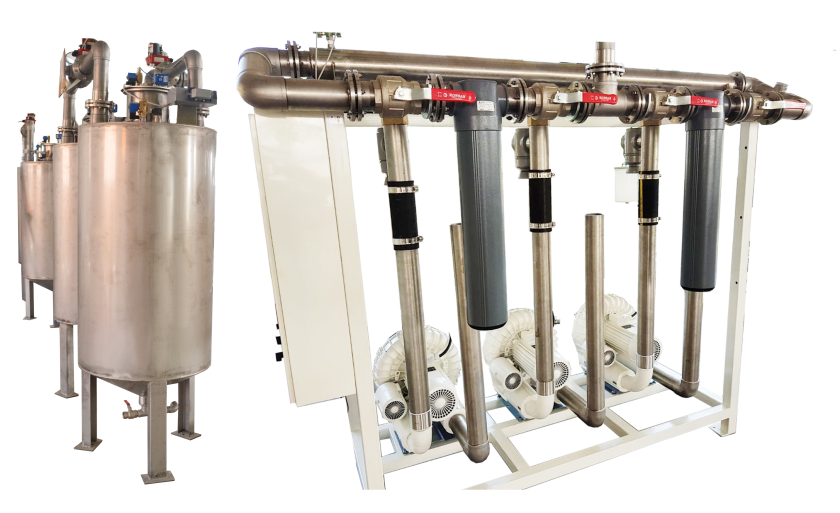

Dental vacuum plants comprise of dry type high capacity radial vacuum pumps, automatically controlled disinfection tanks, bacteria filters and amalgam separators designed to comply with ISO 11143 standard.

Amalgam Separator

Oil-lubricated rotary vane vacuum pumps offer high flow capacities. They are simple and economical to install and operate, and are quiet and vibration free. They provide smooth, pulse-free vacuum and have low starting and running torque.

The vanes are constructed from composite material for a long lifetime of use (up to ten years under normal operating conditions) and low noise levels.

Bacteria Filters

In dental vacuum plants bacteria filters are used that can filter particles up to 0,01μm with a DOP efficiency of 99,9999%.

Disinfection Tanks

According to the plant capacity two automatically controlled tanks are used. These tanks work synchronously under control of the automatic control panel.

Touch Screen Control Panel

- Colourful, touch-screen and easy-to-use display.

- The system has automatic and manual operation feature.

- Adjustable working system up to 4 pumps.

- Audio-visual status display and fault display.

- Fault alarm statuses are designed according to HTM standards.

- Synchron Aging work system.

- Remote access with Modbus-RTU and connection to Hospital BMS.

- Pumps’ temperature can be adjusted as PT100 and dry contact.

- Vacuum measurement units: mmHq and mbar

- The pump information is displayed both on the touch screen and by the LED signals on panel: “cut in”, “cut out”, “defective”

- The pump transition times are preset at the factory, but these transition times can be adjusted according to the tank reserve, capacity requred by the hospital etc. (While one pump is running, reserve pump starts if the running pump does not meet the required capacity.)

- Vacuum start-stop value can be adjusted.

- Display plant pressure and line pressure value.

- Display filter pollution.

- Display power failure, thermic failure of the pumps.

- The pump can be deactivated when necessary.

- System detects deactivated pump(s) and reserve pump(s) will be activated.

- The operation and failure status of the pumps are animated on the touch screen.

- Pump and alarm status are displayed on the panel by LED signals according to HTM standards.

- The PCB system can operate on its own when any fault condition occurs on the panel.

- Pump working hours can be recorded and displayed.

- Language selection (German-English)

- Authorized person access by password.

VAKUM PUMPS

HTM02-01 Dental Compressed Air and Vacuum Systems paragraph 4.39 defines that dry type radial vacuum pumps should have a capacity of max. 25 kPa (250mbar) negative pressure but normally systems are set to 18 kPa (180mbar) max. negative pressure by the user.

Side channel vacuum pumps

- 100% oil-less operation

- Integrated inlet filter

- Integrated vacuum or pressure relief valve

- The compact regenerative blowers offer high performance in a quiet, contact-free environment.

- They require minimal maintenance and can be converted to two-stage operation.