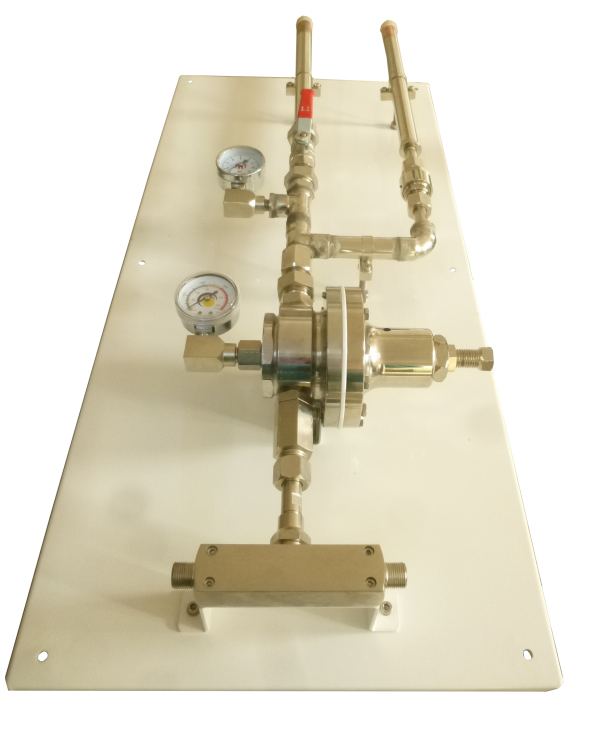

Emergency Supply System

This is a low capacity, manual controlled manifold which can be entered into operation during the maintenance or failure of the system.

It supplies oxygen, nitrous oxide and medical air requirements of hospitals temporarily.

It has no automatic changeover and has just one regulator.

High Pressure Regulator

- The high pressure regulator reduces the pressure of the high pressure gas from the tubes to the pressure that can be controlled by the second pressure reducing regulators. High pressure regulator flow capacity varies according to hospital capacity. Maximum working pressure is 250 bar. Adjustable output pressure value is 0-12 bar. The factory-set output pressure is 7-8 bar.

Safety valve

- There are two safety valves on the right and left sides, after high pressure regulators. The safety valves operate when the pressure in the high pressure regulators increases to 12-13 bar and the gas is discharged into the atmosphere.

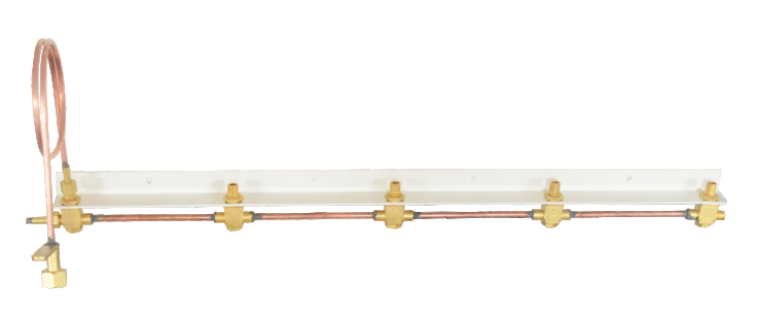

Header

- For each cylinder connection, there is a hot forged brass made tail pipe and non-return valve which prevents back-flow of the gas. They provide connection between pigtail pipes and plant.

Cylinder Task

- Cylinder Rack is used to support and fix the cylinders on the headers.The cylinders are secured by means of chains to prevent them being dislodged and cause a danger to the users and the system.

Tail Pipe

- These are manufactured from Ø8×2 mm Medical Copper pipe and suitable for the connection between the Plant Header and the cylinders.

- They are tested at 250 bar pressure.

Flexible Connector

- Flexible Connection between Ramp and Panel:

- Ø 8×2 mm Medical Type Copper Pipe is used. It is located between Ramp& Panel. Flexible Connection between Ramp & Ramp:

- Ø 8×2 mm Medical Type Copper Pipe is used. It is located between Ramp & Ramp.