Cylinder manifolds are an important element of gas management in hospitals. They ensure the supply with medical gases and control the gas pressure. The core of the system is the Gas Control Station.

The manifold control system shall conform to ISO 7396-1 – Medical gas pipeline systems, NHS Health Technical Memorandum HTM 2022 and HTM 02-01. The manifold control system shall provide an uninterrupted supply of a specific medical gas from equally sized high pressure cylinder banks via a suitable arrangement of pressure regulators, providing a constant downstream nominal pipeline gauge pressure of 400 kPa or 700 kPa. The entire system shall be ‘duplexed’ such that any single functional component failure will not affect the integrity of the medical gas supply. The manifold shall be supplied fully assembled and tested.

Automatic Manifolds provide a continuous supply of gas from two banks of cylinders by automatically changing to the standby bank when the duty bank has become depleted.

Manifolds are available for Oxygen, Nitrous Oxide, Entonox, Carbondioxide and Medical Compressed Air.

These manifolds comprise an automatic changeover panel with alarm & status monitoring, an isolation & relief valve assy, non-return valve, two group manifold headers, two group cylinder racks and tailpipes with gas specific cylinder connectors

MODEL : AMS 3000

FEATURES

- 10″ Touch-Screen Display

- Colorful and easy-to-use display.

- Manual and automatic adjustable working system.

- Audio-visual status display and system failure display.

- Remote access with Modbus-RTU and connection to Hospital BMS.

- The pressure values of the changeovers for the cylinder banks groups can be adjusted both to right or left bank.

- When a fault occurs in the system, the date, time and cause of the fault remain recorded in the reports page.The system shows analogously the values of the left group, right group and line pressures in the manifold system.

- Changeover of Cylinders groups is automatic.

- Pressure measurement units: bar, kPa and psi.

- Cylinders pressure status can be monetarized instant.

- Alarm status is designed in accordance with HTM standards.

- High pressure and low pressure alarm status are adjustable.

- The status of the plant can be monitored by the LED signals on the control panel.

- In case of emergency, manual gas flow is provided by by-pass system.

- The audible alarms can be set to silent mode.

- Language selection (German-English).

- Authorized person access by password.

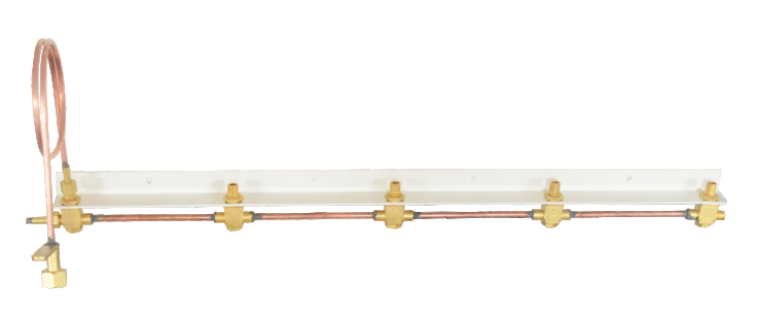

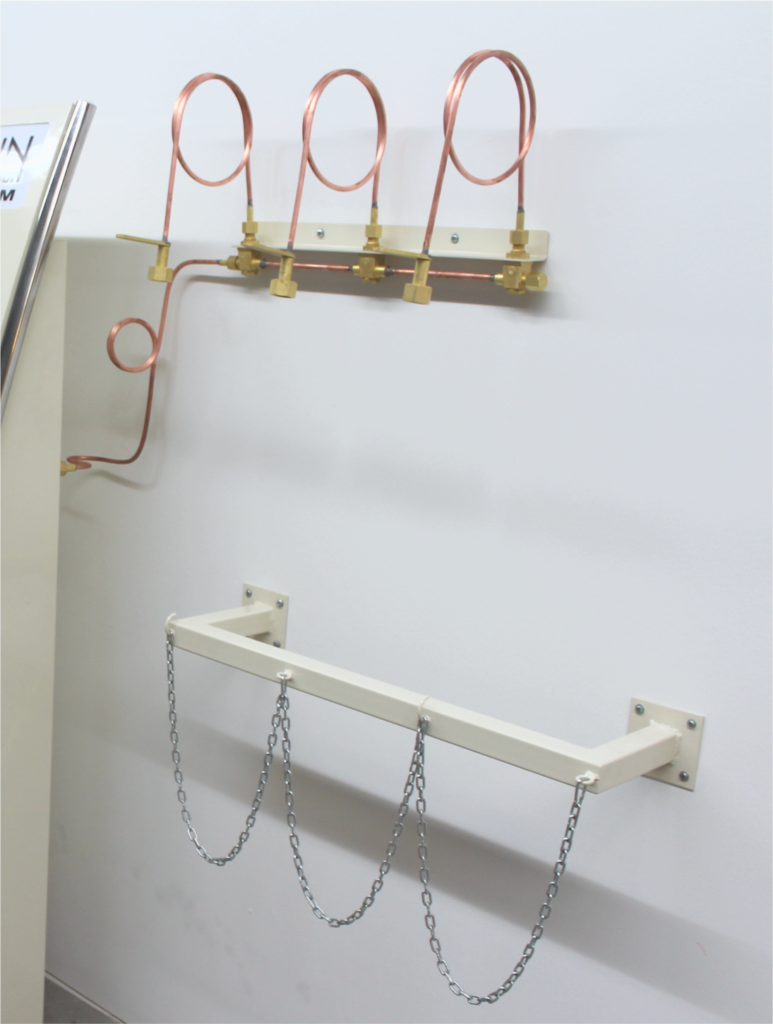

High-Pressure Collecting Pipe

High-Pressure Collecting Pipe manifolds shall provide connection points for flexible copper tailpipes. They shall be available in ‘primary’ and‘ secondary’ configurations, with either single or double cylinder connection points. ‘Primary’ headers shall connect directly to the manifold control system with extensions for additional cylinders being provided by the addition of ‘secondary’ headers. Non-return valves shall be fitted to each tailpipe connection point to protect the system in the event of a tailpipe fracture.

Cylinder Holders

The design allows simple one-handed loading and quick release. The holder fixes permanently to the wall, keeping cylinders clear of the floor to allow easy cleaning and reducing hazards in corridors and doorways. It provides a permanent storage location for cylinders in wards and corridors, controlling the number of cylinders stored within an area.

Flexible Tailpipe

The Schönn copper tailpipes shall have a Ø 8 mm x 2 mm wall thickness, copper tube.

• Maximum 250 bar working pressure on tubing

• All tailpipes 100% tested before shipping and labelled for gas service and pressure rating

• Standard length 900mm