SEISMIC U-FLEX

• The U-Flex Hoses are generally used in four types of applications:

• To correct problems of misalignment

• To provide flexibility in manual handling operations

• To compensate for intermittent or constant movement

• To absorb vibration

• In all of these types, careful hose selection, design of the assembly, and installation are important for optimal service life. The flexibility of a hose is determined by its mechanical design and the inherent flexibility of its material.

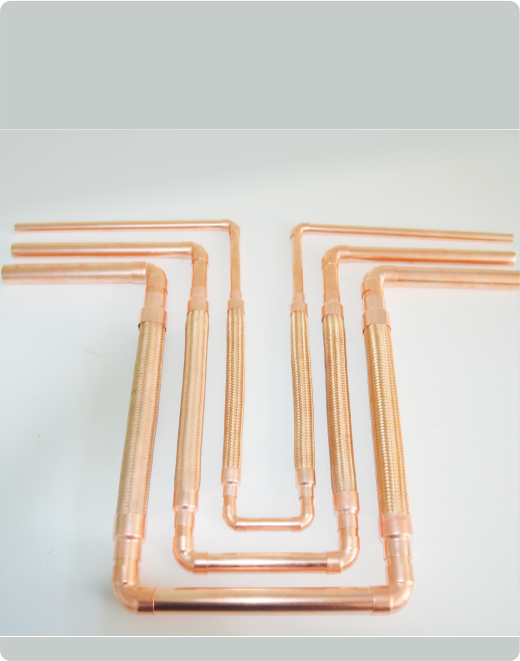

- “U” Design

- Variety of sizes & end fitting combinations

- Nested configurations

- Maximum vibration absorption

Benefits:

- Compensates for offset, lateral and axial motion

- Saves space

- Meets most installation requirements

- Simplifies protection of multi-pipe runs

- Seismic protection of equipment & piping

- The U-Flex Hoses are extremely critical accessories and used for protecting vital installations such as medical gas systems from seismic motion like earthquakes.

- This Seismic Connection Hoses provide flexibility to piping systems and used to absorb possible seismic movements in three axis.

- In addition to seismic protection, installation cost is lower comparing to conventional expansion joints considering lesser need for space and fixing points and ability for nested installations.

- Comparing to use expansion joints and conventional piping to absorb vibrations, imposing lesser load to main pipeline is one of their significant advantages.

- Braided flexible hoses are consist of two parallel sections of braided bronze hose, a 180 degree return bend, with inlet and outlet 90 degree elbow connections.

- The hoses are engineered to move in all three planes, and is impart no thrust loads to system anchors.

- Materials of construction of the Schönn U-Flexes are bronze Hose with bronze braid and copper ends.

- End fittings are made of copper and welded with %5 Brass.

- Seismic U-Flex hoses are designed to meet the design pressure, temperature, and movement requirements for the system.

- Hoses is capable of accommodating piping system and equipment movements and vibration as needed.

- Bronze flexible hoses, braided and their assemblies are designed to allow frequent movement or flexibility.

- Flexible hoses are the standard of the industry in braided connectors for copper piping. This style connector is constructed with bronze flexible hose & braid for high-pressure ratings.

- Flexible hose is off ered with standard copper sweat/tube ends.

- Its nominal size is 15,22,28,35,42,54. Other nominal sizes can be produced in accordance with the customer’s requirements.